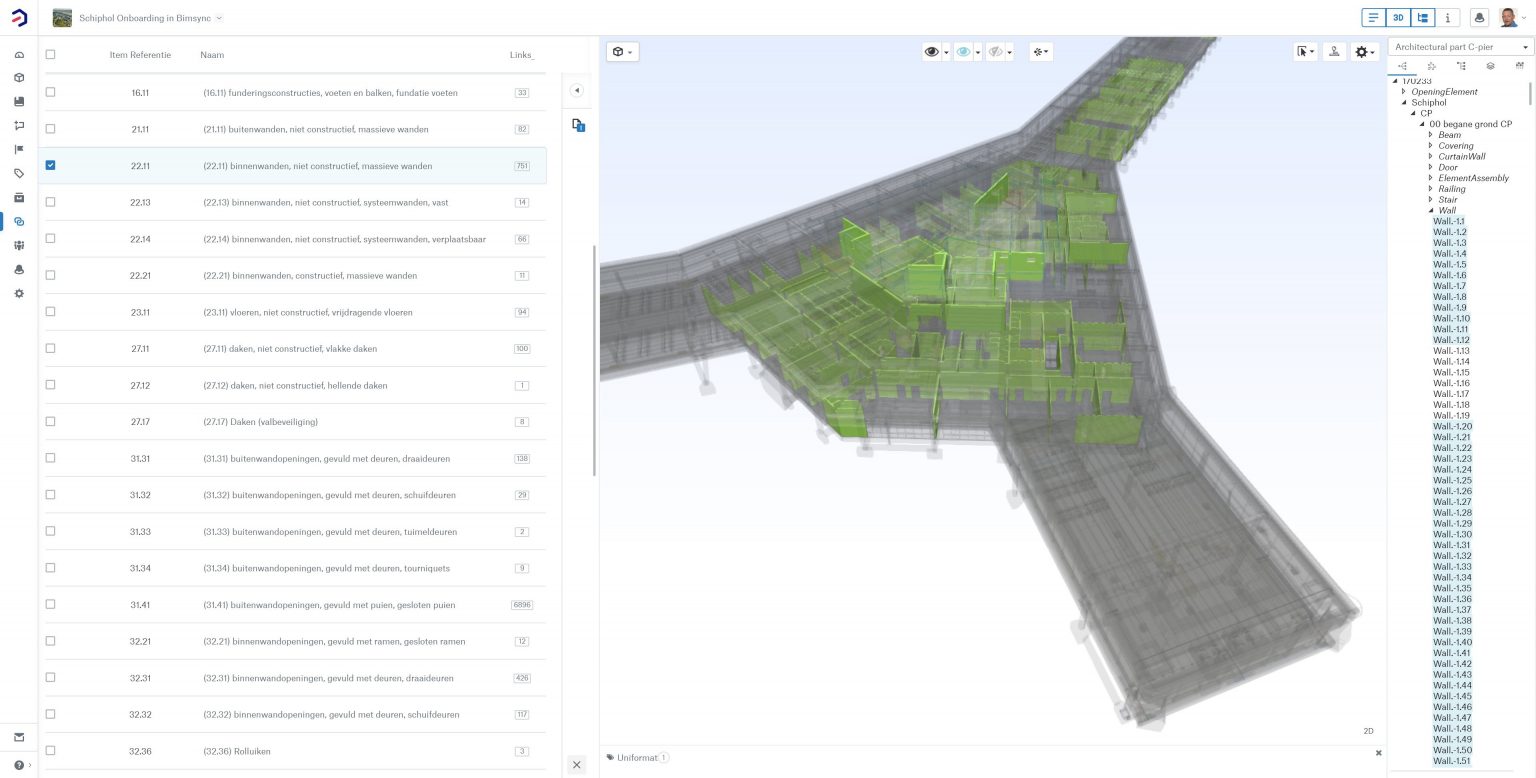

Schiphol Technical Decomposition as the library in Catenda Hub

BIM@schiphol Program

“We are happy with what the BIM program has achieved. We did not only look at tools but also at what it takes to establish digital twins at Schiphol, at processes, organizational structures, and most importantly: Human behavior. Catenda Hub (previously Bimsync) is an application that is easy to use and fits well with the need to store IFC Models, BCF issues, files, and documents, says Stefan van der Weide, Senior Programme Manager BIM@schiphol.

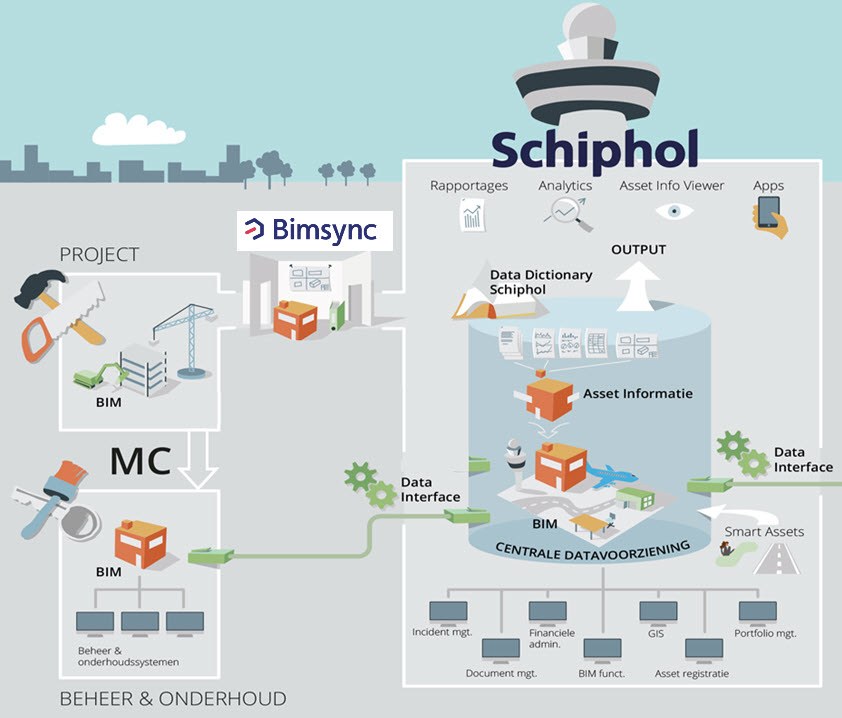

Catenda Hub (previously Bimsync) has an essential place in the total IT landscape that Schiphol uses to pursue an object-oriented approach. Data has a prominent place in Schiphol’s business strategy. The data is stored in a common data environment, and from there it is available for various systems.

The BIM@schiphol Program is a major undertaking that encompasses high ambitions for the entire organization for utilizing the data produced by the multifaceted activities.

Their ambitions are equally high: Using the digital twin, Schiphol is growing into a data-driven organization. This entails becoming an organization that can optimize analyses, processes, and operations with the help of integrated data with which deliveries of new projects to be built are accelerated, failure costs during construction will decrease and the work of employees becomes more fun and challenging.

The joint IT Strategy for 2018-2020 is Make IT Easy, and entails going from multiple service management tools to a central tool. The aim is to become fast and flexible through collaboration with chain partners, using Catenda Hub (previously Bimsync).

“It’s very pleasant to work with Catenda Hub! This is because it is a tool that can be learned quickly, so that project partners do not lose time delivering information products,” says Peter Luske, Manager Project Controls at Schiphol.

It’s very pleasant to work with Catenda Hub! This is because it is a tool that can be learned quickly, so that project partners do not lose time delivering information products.

Peter Luske, Manager Project Controls at Schiphol

The Schiphol BIM journey

The Schiphol BIM journey started in 2010 when they decided to investigate what Construction Information Management could mean for Schiphol. This decision was made at the time to contribute to the vision of Asset Management: the sustainable creation and management of profitable and reliable assets through consistent, uniform and structured information about its assets.

Building Information Management (BIM) was defined as a method to create a digital representation of assets’ physical and functional characteristics. The digitization of this asset data is the basis for a “Digital Twin (1:1) of the airport” modeled in 3D.

Usage of Catenda Hub (previously Bimsync) by Schiphol Airport

In the feasibility study building information of May 2015, the term Digital Twin is for the first time conducted and defined. The truthful 3D models, enriched with assets, with planning and budget information, lay a solid foundation for making analyses that support (management) decisions throughout the entire life cycle of assets.

Advantages have already been gained with various construction projects through the use of BIM software. For example, the inlet at skyport in the steel construction at the corridor to departure hall 1a (temporary terminal). Because coordination of the virtual design has taken place, a “clash” was discovered early. A clash concerns a design conflict between different contractors or different construction projects. Partly due to this coordination, the delivery was not delayed and this saved the construction team a lot of money.

It quickly became a question not of whether Schiphol should further develop BIM, but rather how soon and how.

“Safety has the highest priority. Schiphol also has high-security requirements for the systems. We are pleased that Catenda has provided Catenda Hub (previously Bimsync) with these high demands, like Single Sign On (SSO) so quickly, and that both our supplier Ibis and the AWS Data Centre used by Catenda Hub are ISO 27001 certified,” says Lysette Kampman, Business Consultant Information BIM.

BIM Consultant Hans Hendriks concurs: “Explaining and implementing Catenda Hub (previously Bimsync) is easy. We have created a quick guide and an interactive manual – they are well received, we already had nice reactions: Wow what cool!, Can I also access it?, Can we not use this for all projects?, finally a good platform to share the BIM models!”

Ibis, a software company specializing in creating and selling estimation and maintenance software for construction, infrastructure, and real estate management, was successful in closing a contract with Schiphol. As the exclusive partner for Catenda within the Dutch-speaking Benelux, Ibis has delivered and installed Catenda Hub (previously Bimsync) for Schiphol.

Value optimization

Applying BIM to construction projects and in-process control has many advantages that generate value across the board and contribute greatly to improvements during the implementation phases. For instance, lead times can be shortened because developments in the new assets can be better controlled. Failure costs are reduced because errors can be identified already in the design process instead of only finding out during installation or construction.

All this leads to a higher speed of implementation, at lower costs, and with plan stability. Fewer surprises during rollout also mean more certainty in planning.

What lies ahead?

The results so far are very promising, and now that this software highway is in place, implementation and the cross-organizational roll-out is now being carried out.

Catenda Hub (previously Bimsync) and the use of open international standards will remain at the core of Schiphol´s project organization. This will be key in their pursuit of achieving ever more efficient and coherent ways of data-driven decision-making and capturing data all through the life cycle.